R&D Capability

Be capable of designing and developing vehicle-level platforms and systems, and vehicle testing; IPD product integrated development process system has achieved synchronous design, development and verification throughout the process of R&D, ensuring the quality of R&D and shorten R&D cycle.

We always adhere to the development model of "customer-centered, demand-driven product development", with R&D institutes as the carrier of research and development innovation, and focus on technological brands to expand our business layout. Currently, we have the ability to design and develop vehicle level platforms and systems, integrate design and development of vehicle performance, incubate scientific and technological innovation, and verify vehicle performance. We have introduced the IPD product integration development process system to achieve synchronous design, development, and verification throughout the entire product development process, Effectively ensuring the quality of research and development and shortening the research and development cycle.

R&D and design capabilities

Vehicle design and development: Establish a performance based integrated development system and product platform architecture, use advanced digital design tools and V-shaped development processes domestically and internationally, achieve synchronous design, development, and verification throughout the product development process, effectively ensure research and development quality, and shorten the research and development cycle.

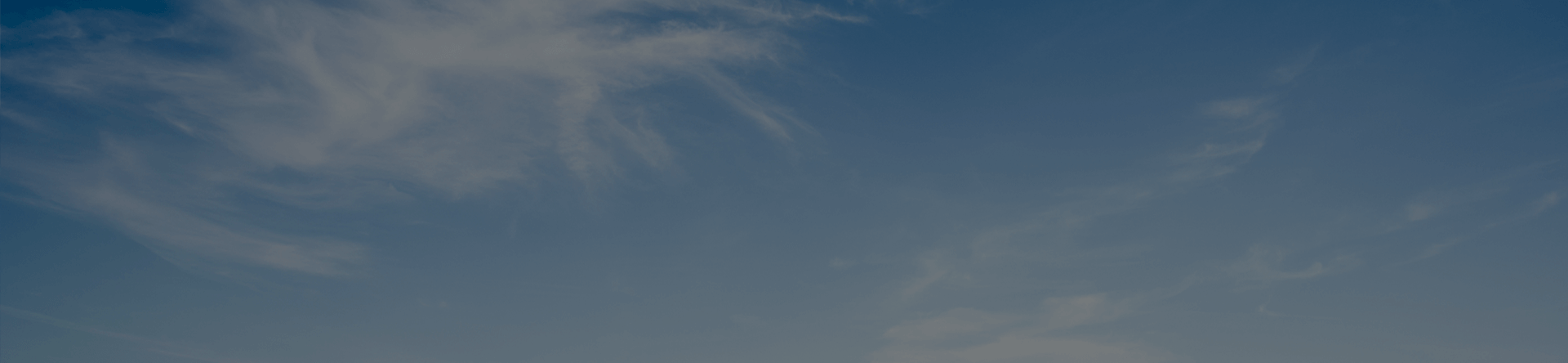

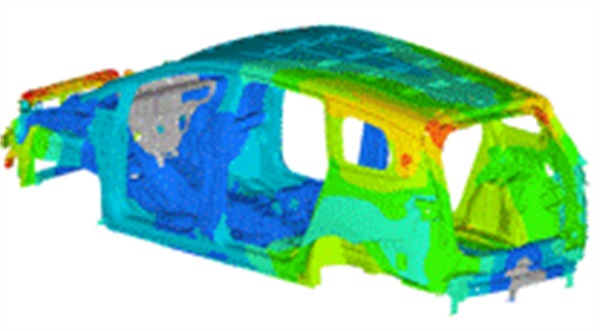

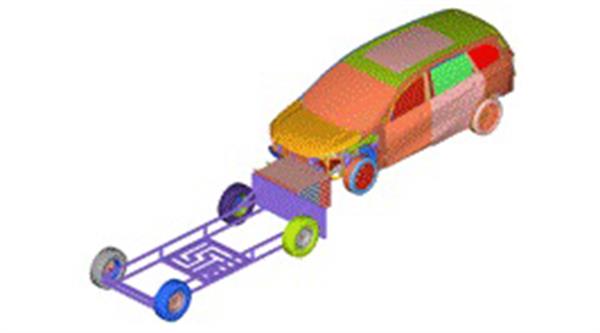

Simulation analysis capability: Possess simulation development capabilities in eight dimensions: structural stiffness and strength, collision safety, NVH, CFD and thermal management, fatigue durability, and multi body dynamics. Create virtual design and verification capabilities with high performance, cost, weight balance, and simulation and experimental benchmarking accuracy

NVH analysis

Collision safety analysis

Multidisciplinary Objective Optimization

Test capability

The R&D and Testing Center is located in the Liudong Commercial Vehicle Base, with a construction area of 37000 square meters and a first phase investment of 120 million yuan. It has built multiple large-scale comprehensive laboratories, including vehicle emission, durable drum, NVH semi anechoic chamber, component testing, electronic and electrical components EMC, new energy, etc. The testing program has been expanded to 4850 items, and the coverage rate of vehicle testing capacity has been increased to 86.75%. A relatively complete vehicle design, vehicle testing, chassis, has been formed Body and component testing capabilities.

Vehicle Environmental Emission Test Laboratory

Vehicle Road Simulation Laboratory

Vehicle road emission test room

Manufacturing capability

The R&D and Testing Center is located in the Liudong Commercial Vehicle Base, with a construction area of 37000 square meters and a first phase investment of 120 million yuan. It has built multiple large-scale comprehensive laboratories, including vehicle emission, durable drum, NVH semi anechoic chamber, component testing, electronic and electrical components EMC, new energy, etc. The testing program has been expanded to 4850 items, and the coverage rate of vehicle testing capacity has been increased to 86.75%. A relatively complete vehicle design, vehicle testing, chassis, has been formed Body and component testing capabilities.

Stamping

The stamping workshop has one fully automatic uncoiling and blanking line, and two fully automatic stamping production lines with a total tonnage of 5600T and 5400T. It produces exterior panels such as side panels, top covers, fenders, and machine covers, with a production capacity of 400000 units per set.

Welding process

The entire line adopts advanced technologies such as automated transportation, NC flexible positioning, laser welding, automatic gluing+visual inspection, robot automatic welding, online measurement, etc., with a robot usage rate of up to 89%, achieving flexible collinearity of multiple vehicle models.

Painting Process

Complete the domestically pioneered one-time dual color vehicle process for line passing;

Adopting cathodic electrophoresis technology to improve the corrosion resistance of the vehicle body, with 100% robot automatic spraying.

FA Process

The frame, body, engine and other major assemblies adopt an aerial cross line automatic conveying system; Adopting modular assembly and fully integrated logistics mode, AGV intelligent car delivery is launched online, and the Anderson system is used to improve quality and efficiency.

Simultaneously utilizing information technology, based on systems such as ERP, MES, CP, etc., to reconstruct business processes, achieve process transparency and visualization, and significantly improve production efficiency

Modeling ability

Be capable of carrying out the whole process design and development of 4 A-level project modeling.

Covering an area of 4000 square meters

Built with VR review room, office area, model processing room, coordinate measuring room, outdoor review room, etc., it can carry out the full process design and development of four A-level project designs

SUV

SUV

Mpv

Mpv

Sedan

Sedan

EV

EV